Coach Battery Upgrade

This is a companion to a YouTube video on the upgrade and goes into a little more detail on the trade offs between wet cell, AGM, and lithium batteries. You can watch the YouTube video here: https://youtu.be/dvhdrzzDqK4

Our coach came with four golf cart (GC2) wet cell lead acid batteries. While we bought the coach used, the previous owner had just replaced those batteries (for the coach) along with the two starter batteries (for the chassis). The chassis batteries are of the “maintenance free” variety meaning they don’t normally outgas nor need water added.

The wet cell batteries on the other hand require regular maintenance: adding water as it boils off in the normal charge/discharge cycle and periodic cleaning of the terminals due to corrosion from the sulphuric acid outgassing. I had cleaned the terminals and protected them but the maintenance chore I had not done was to remove the batteries and clean the tray underneath.

The capacity of each battery is a little over 200 A-Hr, and each battery is a 6 volt unit. So, the four batteries are connected with two in series (to get 12 volts) and then two sets of those in parallel for about 400 A-Hr. of total capacity.

Lead-acid battery technology is mid 19th century (it was invented in 1869 by the French physician Gaston Planté) so it is not new but has been around for a long time. It’s major attraction is the cost of batteries, but they also have some drawbacks. The first (with the wet cell) is the need for regular maintenance as well as the corrosive nature of the fumes emitted. They must always be used in well ventilated spaces.

Newer versions (maintenance free that recycles the natural fumes, gelcells, and absorbed glass mat (AGM)) reduce the annoyance of wet cells, but at a higher cost, as much as 2-3 times for the AGM style of battery. I had looked at upgrading to AGM batteries to reduce the maintenance, but held off doing that until the batteries had aged and started to not work as well. And the major component of lead acid batteries is lead, whether wet cell, gelcell, or AGM, and are heavy. The GC2 batteries I had weighed in at 85 pounds each so a total weight of 340 pounds.

When looking at batteries designed for steady discharge (as opposed to starting batteries that provide a big surge and are then immediately charged back up) such as used in the coach application, they all have a similar limitation: discharging them below approximately half of their rated capacity for wet cells or AGMs (some premium AGMS use 80%) will shorten their service life. AGMs are somewhat lighter than flooded cells and can be recharged with a higher current and so are preferable. They can also be mounted in any orientation if that is an issue.

So, with our 400 A-HR capacity battery bank, we tried to never use more than 200 A-Hr before beginning to charge them back up. We did exceed that on a few occasions but after 3 years of use the batteries were still working OK and I couldn’t see that they had lost much in the way of capacity.

In addition to AGM batteries, I had looked at lithium batteries but had not found them at a price point that made any sense. Other than weight reduction (they weigh about one third the weight of equivalent energy lead acid batteries), it didn’t seem like a good cost tradeoff. They have the advantage of being able to use much more of the rated energy (100% for the Battle Born batteries) so you can possibly get by with lesser amp-hour ratings on the battery bank. They should also last much longer than lead-acid so the total cost of ownership is less when you consider replacing the lead acid batteries more often.

The number of cycles that a battery can withstand will depend on a wide variety of factors (how deep is each discharge cycle, how well is it recharged, how fast is it discharged, temperature, etc.) but a rule of thumb is that a deep discharge wet cell battery will last about 500 cycles and an AGM about 1000 cycles. The Battleborn lithium batteries are generally good for 3000 cycles, and I am told 5000 is not unusual. They also come with a 10 year limited warranty.

More importantly, the Battle Born batteries are good for 100% discharge so you get more effective capacity than the same “rating” on a lead acid battery if you limit it to a 50% discharge as recommended.

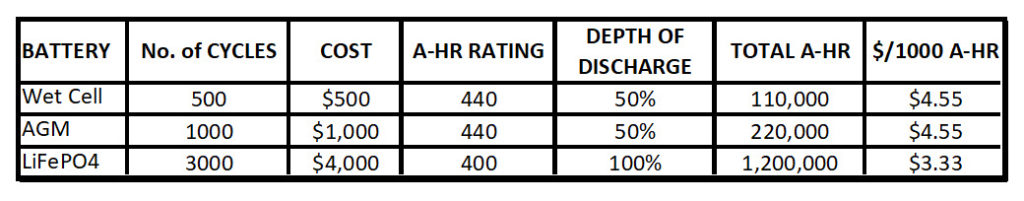

The difference in which type of battery to choose comes down to personal preference and which parameters are most important to you. This chart shows a simplified comparison of the three main types of batteries. Please note that the information shown is typical for batteries and the exact numbers will vary depending on just which product you buy, how well they are maintained, how far they are discharged, etc. The fundamental trade off is going to be initial outlay (dollars spent up front) and cost over the lifetime of the batteries.

As you can see, Wet Cell and AGM have about the same cost for total usable amp-hours over the life of the battery but twice the upfront cost. There is relatively little difference in the weight of the two types, but a huge difference in the maintenance requirements. The lithium technology has a much higher initial outlay but a significantly lower cost of ownership. The maintenance is the same as for the AGM and the weight is significantly less than either of the lead based battery types.

In sizing out batteries, that leads to an interesting choice: we normally can operate just fine with a 200 A-Hr. discharge before recharging, so I could replace my 400 A-Hr. lead acid bank with a 200 A-Hr lithium bank. But, then I would have a problem on those rare instances where I needed more than 200 A-Hr. In the end, I decided to go with 400 A-Hr, the same as before. Since these are 12 volt batteries, I didn’t need to do that, and three would have been a good compromise, but the increased capacity means I can go longer off grid if I want to or before I need to access external power to recharge the bank.

Our coach has a Magnum invert (ME3112 by number) and that became a problem, as you will see. In general, the LIFePO4 technology used in the Battle Born, and other, 12 volt replacement batteries is readily adapted to a 12 volt lead acid battery charger. There is an internal controller as part of the battery that adapts the output of the charger to the needs of the battery and provides other functions as well (cell balancing, temperature protection, charge control, etc.).

The only problem I have had so far with the new batteries has been with charger compatibility due to a particular idiosyncracy with the Magnum inverter/charger in the coach. I set the bulk charge and float charge voltages per the Battle Born recommendations, which is easy enough to do on the Magnum system. But, the Magnum system has a unique “feature” buried in the specifications that I was unaware of: it actually does not maintain the float voltage on the batteries continuously. It has an intelligent feature that, after a period of time, will remove the float voltage and go into a silent or rest state.

In a lead acid battery, if the float voltage is removed, it will drift down in terminal voltage to about 12.7 volts even without a load. The Magnum inverter will reapply a charging voltage when the battery voltage reaches 12.9 volts and thus maintain the charge without over stressing the battery. In theory, this means less stress on the battery and, hopefully, longer life.

In practice, the rest voltage of the LiFePO4 battery is about 13.1 volts, so the Magnum charger never applies a charging voltage until the batteries reach a point close to full discharge and shutoff. i found this out the hard way when our AC lines went out during a storm, and the battery bank was essentially dead because it had not been charging even though we had been connected and charger on. This curve illustrates the issue. The red line shows the rest state of the lithium batteries and the black line shows the point where the charger comes back on; the bank never dropped low enough to trigger the restart.

Magnum has made this a programmable option in later versions of their system, but mine had no way to override this performance. If you consider lithium batteries, it pays to dig into the details of your existing charger to make sure it is compatible.

One of the solutions I looked at (after consulting with Battle Born) was to install a new charger (or converter as the RV industry calls them). A 30 Amp charger would probably be OK as it would run in parallel with the 200 Amp Magnum inverter/charger. I didn’t like this because of installation issues and having one more thing to worry about. The cost for this was around $250 if I installed it myself, which I would.

Another choice of course would be to replace the existing inverter with a complete new system. That would be the most expensive solution but would replace the existing unit with a newer one which would, perhaps, have a longer life.

Magnum was helpful and I found that the controller I had could be upgraded to the latest firmware and allow me to program around their cut off feature. I would have to return the controller to them to load new software and pay the shipping both ways.

The inverter, however. would take a hardware upgrade to replace the controller board. And I could replace the control panel with an upgrade version that had more features than the existing controller. This is the solution I chose as the package (new control panel and replacement controller board) was about $100 more than adding on a new, separate charger, and far less expensive than replacing the entire system.

The process of replacing the control board was simple and easy. The hardest part was getting the inverter out far enough to get the cover off. After that, it was no problem at all. The new controller was just a matter of removing the existing controller and plugging the new on in with the cable that was already in place. Since making this upgrade, the batteries are charging just fine and doing exactly as expected.

When I installed the new batteries, I found that the existing golf cart batteries were somewhat smaller than the new Battle Born units and would not just drop in where the old ones had been placed. I had excess room, so it wasn’t a real issue but if you contemplate making this change, make sure to check the actual dimensions to be sure they will fit. Note that the Battle Born batteries can be installed in any orientation so that can make it easier to get them into tight spaces.

IN addition to the Magnum shore powered inverter/charger in our coach, I also have 960 Watts of solar panel on our roof. On a clear day, that system can deliver 70 ADC or more of charging current to the battery bank. I simply set the charge voltage and float voltage to the levels recommended by Battle Born and have had no problems using the solar system to charge the batteries.

The advantages that I have gained from this upgrade are: first, simplified maintenance. No longer do I have to worry about topping off the batteries with distilled water or cleaning up the terminals and battery compartment from the effects of battery acid fumes. Secondly, I now have 400 A-Hrs of usable battery capacity which doubles my time of battery operation so I am able to stay off-grid longer while camping and can go longer between needing to recharge the batteries. Third, I have reduced the weight of my coach by 220 pounds.

I am pleased with the results, and other than the farkle with needing to upgrade the existing inverter/charger to make it compatible, the installation was not complicated or difficult. the inverter/charger was just an extra expense that was not contemplated when making the decision to do the upgrade.